Building with cork

Cork forests

Portugal is not only known for good wine and beautiful beaches, it is also the largest producer of cork, more than 50% of the world supply comes from this country, before Spain, Morocco and Algeria.

Natural cork originates from of the bark of the cork oak tree (Quercus Suber), which is indigenous to the Mediterranean region and northern Africa. The first harvest of a tree can be made after approximately 25 years and the bark renews itself naturally every 9 to 12 years. The cork oak forests in Portugal, called Montados are an important contribution to the biodiversity and balance in the ecosystem. The cork is present throughout the country, but especially in the Algarve and the Alentejo plains, and occupies 22% of the country’s forest area.

It is important to preserve these forests, because it is home to a number of mammals, reptiles, birds as well as the Iberian lynx, the world’s most endangered feline species. The montados are part of the Portuguese cultural heritage and contribute to the regional identity.

Properties and uses

Cork has some remarkable qualities and can be used for many different purposes, it is even applied in space as thermal insulator for space shuttles. It is light, durable, elastic, waterproof, fire retardant and has great insulation properties. Furthermore, it is 100% reusable. The structure is composed out of tiny gas-filled cells, creating a huge disproportion between the volume and the weight of the material, more than half of its volume is air.

These properties make cork incredibly useful as a building material, whether as flooring, insulation sheets or surface finish. The cork can have different shapes: insulation panels, coatings flooring, cork stoppers, composite agglomerates, raw material.

If the material is used raw and 100% natural (if the process is free from chemical substances), it can provide an ecological alternative to conventional solutions, not least because of the barks ability to absorb CO2 during the regeneration process. Regularly harvested cork trees store 3 to 5 times more CO2 than those left unharvested.

THE PRODUCTION PROCESS OF CORK INSULATION

Working mainly on architectural projects in the North of Portugal and looking for a local material to integrate a vernacular approach, we were interested in the potential use of cork in construction.

We recently had the opportunity to use this wonderful material in two important projects and with different applications. In this article, we will describe the cork applications we tested and the methodology we used.

Like all our research, we paid attention to have the most sustainable applications with: relatively low cost, simple process and possibility to re-use the cork panels.

| ADVANTAGES OF CORK INSULATION |

| 100% natural and fully recyclable |

| Excellent thermal and acoustic insulation |

| Easy to apply ( However, cork is fragile) |

| Mechanical stability |

| Great behavior in large temp. range (-180ºC to +120ºC) |

| CO2 sink (Carbon Negative) |

INSULATION WALLS AND ROOFS WITH CORKS

The walls

Currently, we are finishing the renovation of a modest house for a family as a part of our Post-Graduation in Sustainable Architecture, in partnership with the municipality of Esposende.

In order to improve ceiling height and spatial quality, the roof was taken off and made new. We used the opportunity to insulate the new roof and built an exterior insulation system on the walls that had none. Like many buildings in Portugal, the Esposende house did not have any insulation .

The challenge was to find an economic and ecological solution to improve this. In the case of the rehabilitation, we faced a series of challenges:

- The walls were far from being anything close to straight.

- We wanted to avoid the glues and mortars that are very often used in cork solutions in architecture (like in the ETICS system).

So we used this cork insulation system:

1. Regularize the walls a bit, enough to limit protuberances from the wall from the line we aspired to follow.

2. Setup vertical supports on the wall, starting from the edges, following three horizontal thread lines, in order to transform a twisted wall into a straight support for our system. To protect the wood, we have applied a mix of natural oils (Read more about natural wood protection in this article) and have placed 5 cm stone wedges under the wood to avoid any contact with the floor and prevent it from rotting. Between each of these posts will come the 5 cm layer of cork.

3. Cover the walls with a first layer (1 cm) of cork, below our vertical supports, fixing them with screws and wall plugs directly in the wall. A thin board is better to fit the shape of the walls without leaving empty spaces. This layer is thought to prevent thermal bridges between the 5cm layer of corks coming next. For this reason, the two layers should overlap in a tile fashion.

4. Superpose another cork panel of 5 cm on the first board and between the vertical battens. Making sure to have continuous overlap between the two layers.

5. Fix horizontal structure on the vertical ones every 40-50cm from each other to hold the cork panels (5cm). These horizontal support will allow a wedge to sit between themselves and the 5cm cork boards, to secure the ventilation of the system and pressure the cork boards together and bear the board and batten system.

6. Set up the board and batten system on top of the horizontal structure set up in point. Depending on the wood you’re using, avoid putting two screws horizontally on the boards to avoid cracking. The boards should be free of movement and have at most one or two nail/screws set up on the vertical plane. The battens are the one pressuring the boards in place.

The roof

For the roof, we optimized the use of material to ensure the most sustainable application, as with the walls. Thus, we only used four layers: cork panels, vapour barrier, wood and finally roof tiles. We used a corkboard of 8cm with overlapping joints to secure the potential thermal bridges. The cork boards used for the roof are overlapping to avoid thermal bridges. From the original 1000*500*40mm boards, the manufacturer cuts out 40mm on two perpendicular sides to allow the overlap.

We decided to follow the sarking technique. The sarking method allows us to have a continuous and homogeneous insulation, without thermal bridges due to the frame.

And internally we benefit from the timber structure that can be seen inside the house!

Here are the different steps:

- Lay the cork board directly on the rafters. We used very thick cork panels to avoid using OSB as a roof support. These panels made of sheets of resinous wood assembled by a synthetic resin have the defect of not being very breathable.

- Cover the cork panels with a vapor barrier, this material is used for waterproofing to prevent interstitial condensation of the roof and finally to allow eventual humidity to go out.

- Grid the roof with vertical and horizontal battens. They will serve as a support for the tiles and will allow a complete ventilation of the roof.

- Set up the tiles.

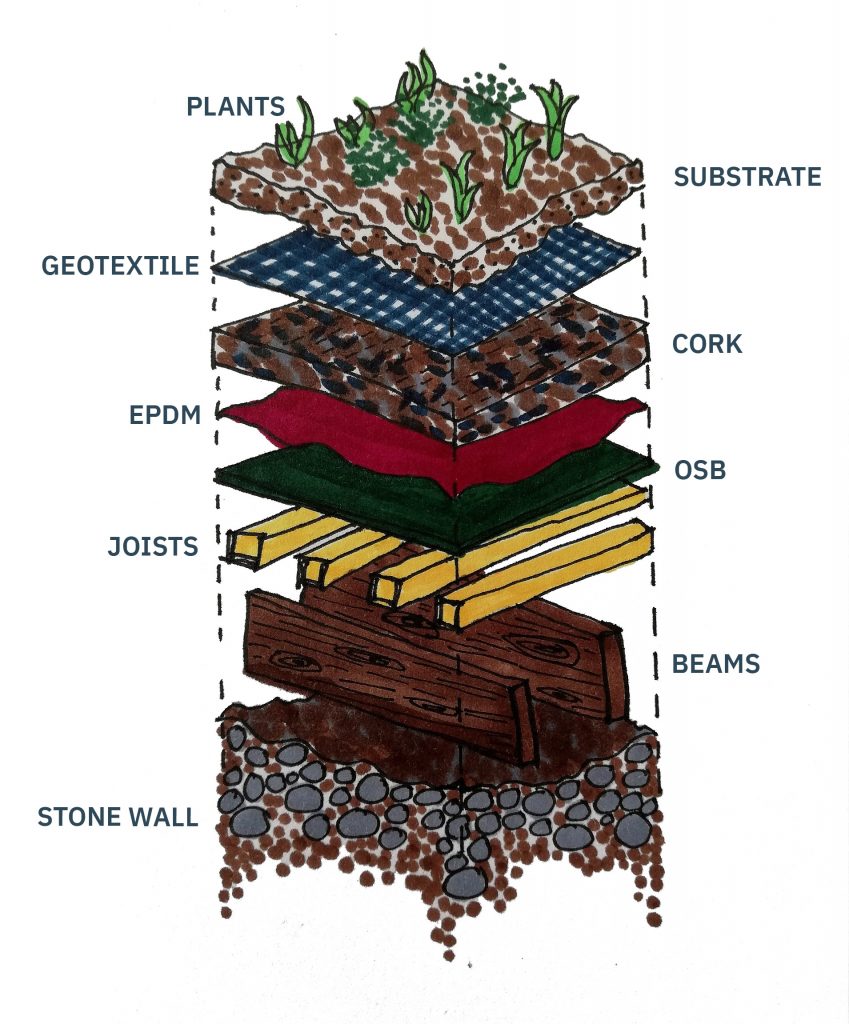

GREEN ROOF WITH INSULATIVE CORKBOARD WITH INTEGRATED DRAINAGE SYSTEM

We decided to use cork for another architecture project last year, a sustainable green roof. A vegetal roof of 140 square meters covering all the top of the workshop. In this article, we will only explain why and how we used the cork, but if you want to learn step by step how to build a green roof, we advise you to watch this video.

We used cork for a triple goal: insulation, drainage and water retention, in partnership with Neoturf, who investigated this possibility and designed the board. The grid on the top side of the board was meticulously designed to allow for a high flow of water drainage. It is necessary for a roof to withstand frequent torrential dumpers and by using this system, we negate the need for synthetic insulation and plastic drainage cups.

These cork boards provide insulation with a thermal efficiency of 0,038 à 0,040 W/mK* on average, which is comparable with material with synthetic sources such as expanded polystyrene.

On the top, to protect the cork from the plant’s roots and substrate a geotextile is added to prevent silt and other particles from the substrate from clogging the grid drainage system within the cork. Activated clay balls surround the borders of the walls, windows, and wooden barriers, and provide additional drainage and fire protection.